Laser blanking for burr-free forming process

By OEM Update Editorial June 16, 2020 2:51 pm IST

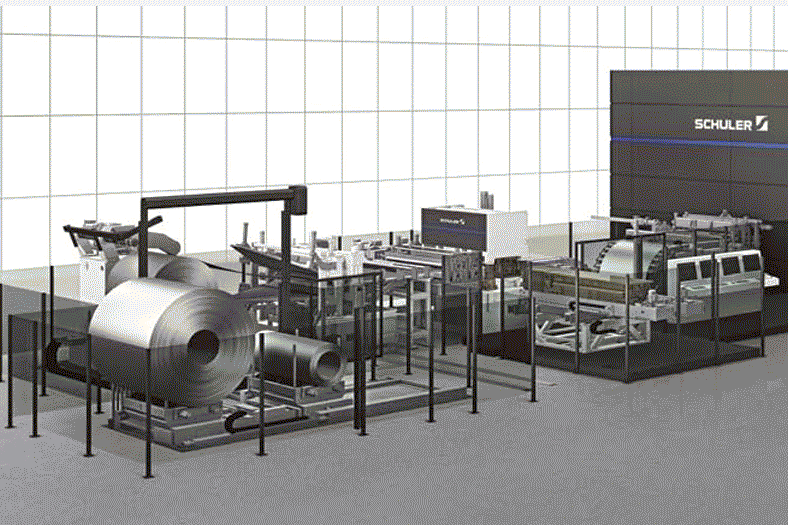

Renowned car manufacturers in Europe benefit from the advantages of the Dynamic Flow Technology and show how it works. Schuler’s powerful and efficient laser blanking lines already supply press lines of many OEMs and TIERs. As a result, complete sets of blanking dies could already be saved on new models — with around a dozen dies per vehicle. This results in a cost reduction in the million US dollar range. But in addition to these savings, OEMs and TIERs also benefit from the use of laser-cut blanks in the downstream forming process.

The amount of aluminium in cars and commercial vehicles is increasing because the lightweight material improves performance and reduces fuel consumption and emissions. However, the surface-sensitive material confronts processors not only with the challenge of gentle handling during blanking. Furthermore, aluminium tends to produce burr on the lower cutting edge.

If this burr detaches and remains as flitter in the forming die, it leads to marks on the material surface, which are still visible even after the painting process, and thus to scrap parts. To avoid those marks in the forming process, extra equipment such as burr vacuum cleaners or blank cleaning systems are required as well as regular line stops for cleaning the forming dies. Depending on the parts, this can result in a five- to 10-minute production interruption after just a few hundred strokes.

Aluminium blanks produced on a Schuler laser blanking line not only meet the high-quality requirements of the automotive industry but also create hardly any burr. By eliminating the need for regular cleaning, laser-cut blanks thus increase the productivity of press lines.

Optimisation of the tryout processes

In principle, the flexibility regarding contour adaptation is already known from the laser-cut blanks from the tryout process. Depending on need, laser cutting programmes can easily be adapted and customised blanks can be produced in small batches without dies. Compared to the flatbed lasers usually used for this purpose, the blanks from a laser blanking line are not cut out of a rectangle, but directly from the continuously running strip material of the coil.

If we assume a scrap separation and good part stacking automated with robots, a scrap grid with a width of approx. 0.8’’ to 1.2’’around the good parts must be considered. In addition, the use of rectangular blanks also results in a waste of approx. 2.4’’per side, which could be used for the next hood blank, for example, when cutting from a continuous strip (see blue dotted area in the diagram).

So if a rectangular blank of 89’’x 87’’ were required for two hoods on a flatbed laser, a laser blanking line would only need a feed length of 81’’ mm and a coil width of 85’’. This would correspond to a material saving of about 11 percent. Regardless of whether the parts are purchased or manufactured in-house, material saving is always also cost saving.

In addition to the aspect of material savings, the much higher output rates also speak for cutting in Dynamic Flow. While flatbed lasers can generally produce between two and three of such blanks per minute, the output rates for hoods on a laser blanking line, for example, reach up to 35 parts per minute with an overall equipment efficiency of over 80 percent. This means that about 1,700 parts can be produced in one hour.

Depending on the sourcing strategy, either small tryout batches can be run flexibly and at the push of a button on the company’s own laser blanking line between series production, or can be purchased at short notice from a supplier with a laser blanking line. These result not only from the fact that production can be carried out faster, but also because the upstream cut-to-length process can be saved. Thus, the tryout process can be optimised by using a laser blanking line with regard to two aspects: cost reduction through material savings and more flexible procurement options.

Changes during series production made easyThey don’t happen often, but sometimes they do happen: changes during series production. One example is the shift to a material with different flow behaviour. While adjustments to the forming or cutting die require pre-production and tooling work, laser-cut blanks can be easily modified in their contours and the changeover to the new material is simplified.

The previous status can also be restored at any time. This also offers the opportunity to try out optimisations — for example, to save material — without much effort or risk. Even small material savings of one or two percent mean that, with an assumed production per blanking line of approx. 30,000 t steel and 10,000 t aluminium, a saving of up to 600 t steel and 200 t aluminium per year can be achieved.

A laser blanking line makes it possible to simply benefit from the potential of material savings even during series production and, in the event of changes, to benefit from the reduced time required for die work.

Advantages at a glance

- No cutting die set required: Savings in million US dollar range

- No aluminium flitter: Regular flitter cleaning time of approx. 5-10 minutes can be saved

- Material savings of 5-10 percent per part for the tryout process (compared to flatbed laser)

- Material savings in series production (already 1.5 percent means about 450 t less steel and 150 t less aluminium per year)

- Uncomplicated contour adaptation during series production.

For more information, please visit: www.schulergroup.com/laserblanking

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.