Constant pressure for machine tool by Grundfos

By OEM Update Editorial May 12, 2020 4:42 pm IST

The Mayfran Company, with more than 1,000 employees worldwide and production sites in the United States, Europe and Asia, is one of the leading global manufacturers of conveyor and filtration systems for the metalworking industry. Mayfran’s reputation throughout the world is evident in this current project: N3 Engine Overhaul Services (a joint venture of Lufthansa Technik AG and Rolls- Royce PLC) has established a plant in Arnstadt, near Erfurt, for the reconditioning of Rolls- Royce power units. N3 assigned Mayfran with the planning and installation of a central cooling lubricant filtration system for the supply of eight machine tools with water-soluble cooling lubricants. The central system (band filter installation) is located in the basement and supplies the machine tools with up to 500 l/min cooling lubricants in 3-shift operation, six days per week. Regardless how many machine tools are simultaneously running, each machine tool must be continuously supplied with cooling lubricants at a pressure of 3 bar.

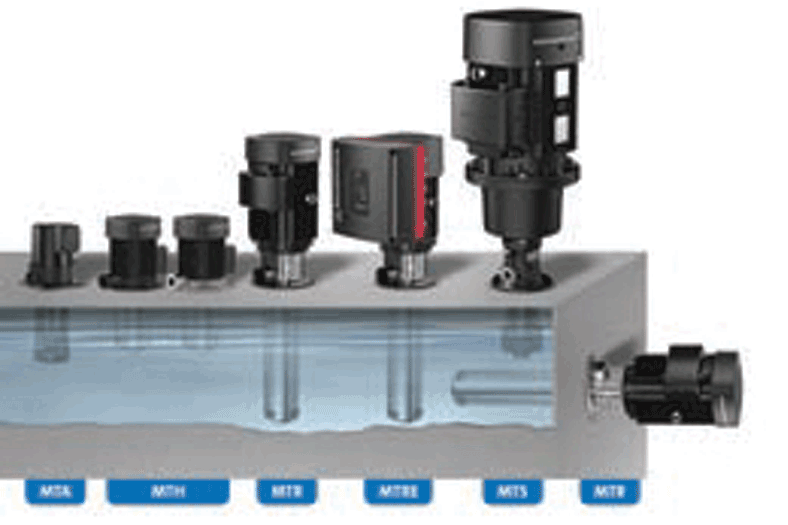

To meet this requirement, the filter installation is equipped with two immersible Grundfos pumps (change in 24-hour rhythm). The units of the MTRE series selected by Mayfran feature frequency controlled motors.

The special characteristics of this series include:

• The cartridge mechanical seal can be replaced without disassembly of the pump.

• Flexible immersion depth: Pump length can be adjusted to installation conditions.

• A suction cycle protects the pump against dry running.

• Pump parts made of stainless steel, optimised suction chamber and impellers.

• Leak channel to tank.

• Energy-efficient high performance motor (EFF1).

Explaining why the cooling lubricant must not heat up, Klaus Bock adds that especially the grinding machines are very sensitive to temperatures and require a preferably constant cooling lubricant temperature for processing a workpiece within the specified narrow tolerances.

For more information, please visit:

www.grundfos.in

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.