Paint shop of the future: away from the line, towards the box

By OEM Update Editorial March 13, 2020 2:16 pm IST

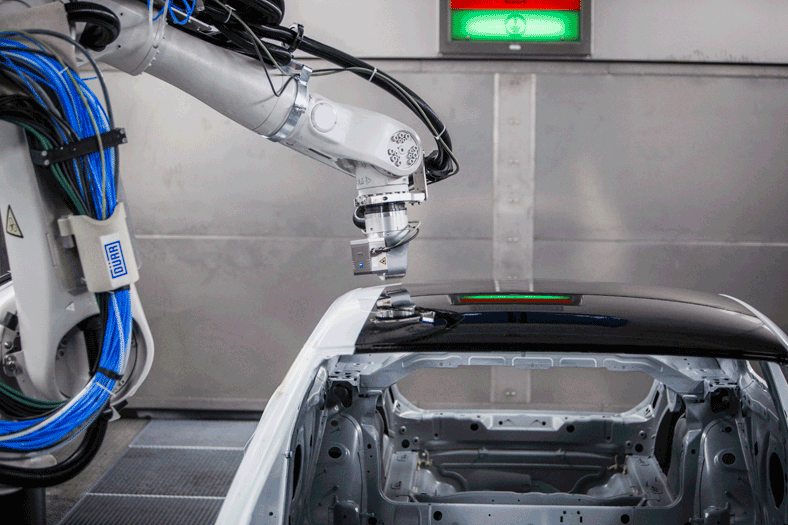

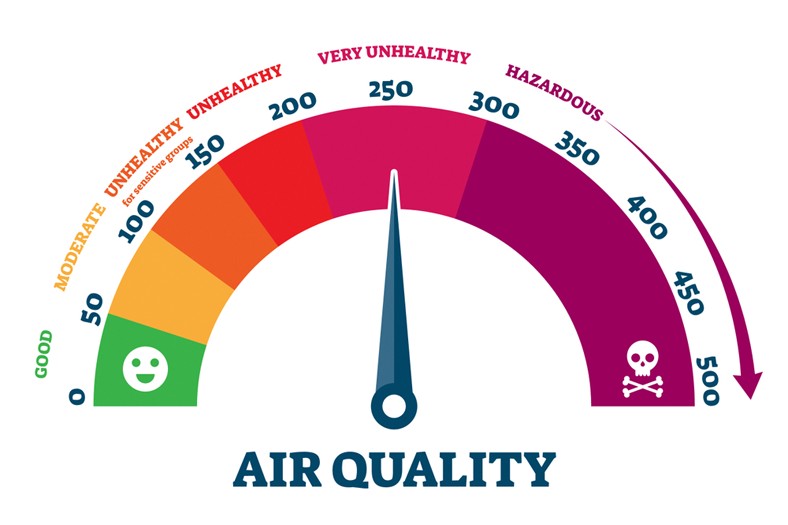

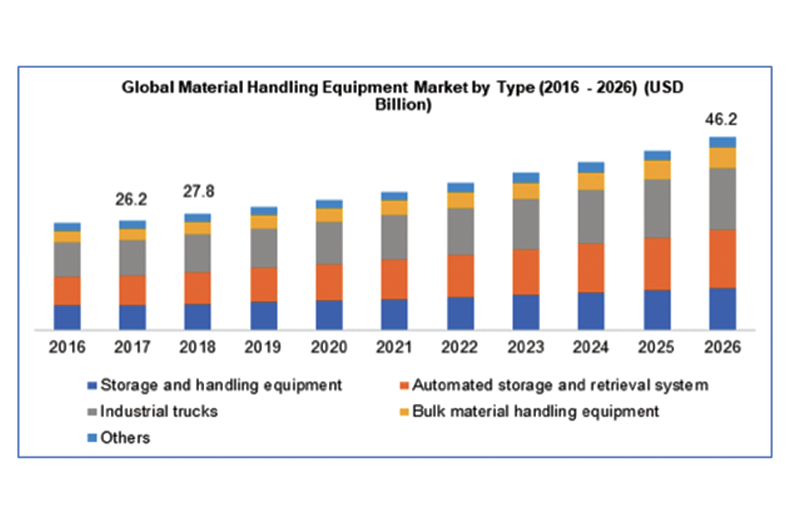

G rowing model diversity, different drive technologies, and greater personalization are pushing conventional line manufacturing to its limits in the automotive industry. Whether major high- volume manufacturers or small e-car startups, manufacturing has to make the switch from rigid to flexible to be able to respond more quickly to customer and market requirements. Dürr’s new “Paint shop of the future” concept breaks away from the traditional line layout, splitting up industrial automotive painting into boxes or short process sections for the first time. This allows the automotive industry to paint in much more flexible manner. In addition, the “paint shop of the future” saves time and material, increases availability and makes painting more sustainable.

Model ranges and application processes are becoming more diverse. But the greater the variety of models painted on a line, the more inefficient the process. This is due to the fixed cycle times, which are based on the biggest model and the paint with the longest application time. If smaller car bodies could be transported faster and some colors could be applied more quickly, this would save time and increase output. However, the fixed cycle does not allow this.

This was one of the many reasons that prompted Dürr to have a rethink and develop a radical new layout for future requirements. “With the “Paint shop of the future”, Dürr is reimagining the painting process and moving beyond the boundaries of the production line,” explains Bruno Welsch, member of the Board of Management of Dürr Systems AG. “The new approach adapts to the needs of manufacturers, and enables an efficient and flexible painting process in every production scenario.”

On-demand cycle times

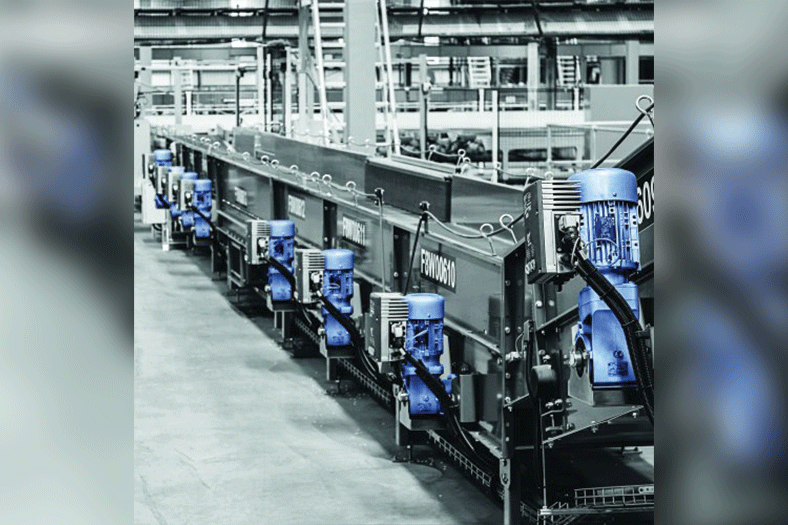

The general idea of the “Paint shop of the future” is based on splitting up the 120 work steps involved in a painting process into boxes and smaller sections. Instead of a fixed cycle, the process times in each box are precisely adapted to the needs of the individual body. This is made possible by processes running in parallel in the boxes and the interaction with a central high-bay storage system and the automated guided vehicle system EcoProFleet. The fleet of AGVs is controlled by the software DXQ control. It guides the AGVs with the car bodies properties combine to reduce CO2 and VOC emissions. intelligently to the next processes, and in this way ensures efficient utilization of all the boxes. It enables the bodies to be sorted in anticipation of future processes, brought to and collected from the right workstation with pinpoint accuracy, and passed off to final assembly at the end in the sequence planned by the manufacturer. The concept also enables easy expansion of capacities or smooth integration of new models. The revolutionary box concept can be applied to the entire top coat and workstation area, or just too selected process steps.

In terms of the concrete implementation, the box concept means that three painting processes – the inner and the two outer applications – can be combined in just one booth. This patent-pending concept, the EcoProBooth, thus helps to save process time, since two of the previously usual three conveying processes are eliminated. The paint-loss during the color change process can even be reduced by up to ten percent if just one paint is applied in a box, for instance the current top seller white. Splitting up the painting process into boxes shortens the overall process by tailoring the application time to the individual vehicle. These

overall equipment availability also increases, since any malfunction only has an impact on the box section in question and does not affect the entire production line, in contrast to the classic line manufacturing model. The variable layout also makes integrating special processes such as a special paint supply or overspray-free two-tone painting easier and more cost efficient.

Adaptable to both large and small production

The concept of the “Paint shop of the future” is geared towards the specific requirements of various OEMs. It offers major high-volume manufacturers with a high hourly capacity the opportunity to integrate new models and technologies with greater ease. It enables companies that want to avoid investment risks to predictably expand from 24 units per hour to 48 and 72 units in two steps.

Newcomers to electric mobility can start their manufacturing with minimal quantities and gradually expand as demand increases. The modular concept is also Industry 4.0 capable and can be combined with the intelligent software products from Dürr’s DXQ family for various scenarios. In this way, Dürr analysis tools make painting processes more transparent and help to further increase the first run rate.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.