igus expands 3D printing service for injection moulding with printed tools

By OEM Update Editorial March 7, 2020 11:07 am IST

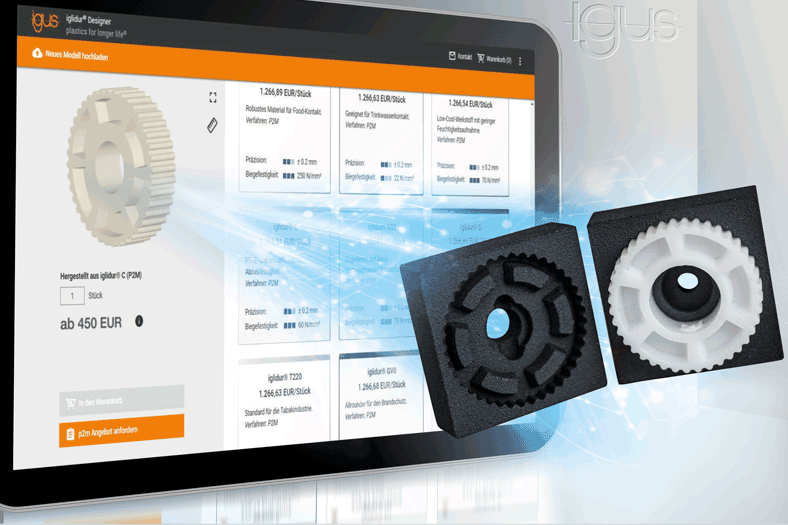

Wear-resistant parts are used wherever there is friction between two surfaces. For this reason, designers in many industrial sectors rely on 55 long-lasting, lubrication-free, high-performance polymers from igus. To help users quickly get their special solution made of a suitable material, igus has now integrated the Print2Mould process in its online 3D printing service. With a printed tool, the component is manufactured by injection moulding. To do this, the user simply uploads the STEP file of the wear-resistant part into the 3D printing service, selects the material and requests a quotation. Specifications on the material properties as well as the precision, flexural strength and the price help with the choice.

If customers are looking for a wear-resistant plain bearing, they can choose from a large selection of igus materials. However, if customised wear-resistant parts are required — from gears up to special bushings — in any special shape, the user can either machine the component from a suitable iglidur bar stock or use igus’ 3D printing for more complex geometries. For the individual component to be made from the ideal iglidur material for the respective application, igus offers the Print2Mould process. In this process, an injection moulding tool is printed for the special solution and is then used in the injection moulding machine. The main advantage is that the user can freely use the iglidur material range with its 55 lubrication-free, high-performance polymers. These include the FDA-compliant materials iglidur A350 and A181 for use in the food industry, iglidur L500 for the automotive sector, and iglidur X for high-temperature applications. igus has now integrated the Print2Mould process in online 3D printing service. The production of special parts by this process is characterised above all as a time-saving solution for prototype development and for small batches. This gives the customer the opportunity to obtain identical components in batches at an early stage of development.

Wear-resistant components requested onlineThe way to a lubrication-free and maintenance-free special solution is very simple: call up the 3D printing service at www.igus.in/iglidur-designer, upload the STEP file of the component and select the appropriate material. In addition to the 55 iglidur materials used in the Print2Mould process, the customer also has the opportunity to get their special solution printed cost-effectively in the SLS process with the wear-resistant materials iglidur I3 or iglidur I6 or even in the FDM process with iglidur filaments. The price for production, including the costs for the injection moulding tool as well as information about the material, precision and flexural strength, are shown online. After selecting the appropriate high-performance polymer, the user can enter the quantity and directly request a quotation from igus. The injection-moulded special solutions are delivered after 10 working days.

For more information, visit:

www.igus.in

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.