Connotation of spark erosion oil in Electric Discharge Machining

By OEM Update Editorial March 2, 2020 3:21 pm IST

Electric Discharge Machining, or EDM, is becoming a popular process of metalworking with being widely adopted by the manufacturers. It gives them the ability to work on cynical metals and ceramics to make small and incredibly complex components, with accuracy. EMD can mainly be found in the diverse industries like aerospace, automobiles, sports and surgical instruments among the others.

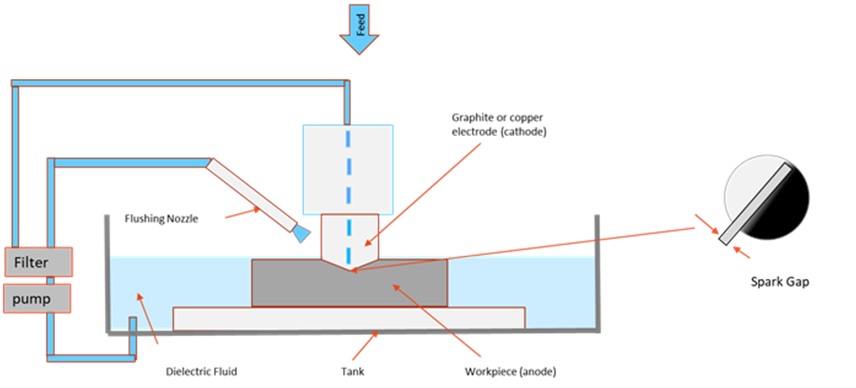

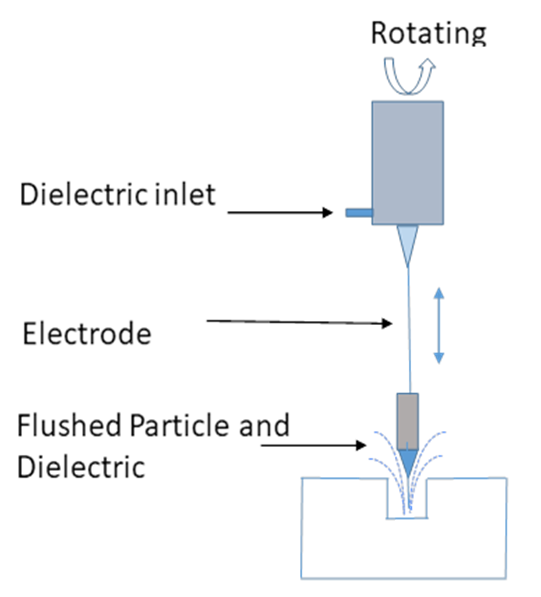

In this process, metal is worked by applying heat to it, through an electric spark without involving and touching the tool and the work material. The process is also known as ‘spark erosion’, where the tools and materials are connected to a D.C. source via a cable. Electric current is then fed and the tool and material are slowly brought closer together. When the gap is less, it ignites a spark that then erodes the metal.

However, key to this reaction is the ‘Spark Erosion Oil’ or the dielectric that acts as an insulator, conductor, coolant and cleaner, which has to be immersed to the materials for better processes.

When the ‘spark gap’, as the distance between the tool and material is narrow enough the fluid ionises, opening up a conductive corridor that allows the spark to ignite erosion. When the spark stops, it cools the material which can be between 8,000 to 12,000 °C. Moreover, it plays a vital role is flushing away the eroded material that may otherwise render the process inefficiency, damage the tool, result in a higher wear rate of the electrode but doesn’t erode the metal fast enough. The fluid is comprised of what components and substances?

Electro Discharge Machining (EDM) can trace its roots back to 1953, when two Russian scientists realised the erosive effect of capacitor discharges could be applied to the processing of metals. The scientists B.R. and N.J. Lazarenko first used air as a dielectric. But, later they concluded that mineral oil-based fluids were far more suited to the process.

Today, there are a multitude of EDM oils available in the market place, having their own insulating, conductive, flushing, ionising, viscosity and cooling properties.

Regardless of their composition, they all need to have stable dielectric strength to provide adequate insulation.It should be able to flush out the particles produced during the erosion process by being chemically neutral and having a high flash point and be fire resistant. It should neither emit toxic vapours nor unpleasant odours. Above all, it should retain all these properties despite temperature variations, contamination of eroded particles and those that result from decomposition.

Authored by:Jogesh Sharma, Head – Industrial Lubricants, GP Petroleums Ltd.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.